The problem:

On previous Durmitor trips to the northern region we've gone for hand bolting: we hadn't really found enough significant to warrant the weight/time/expense of sorting a drill option. This year with potentially two significant vertical caves still going, a drill or two seemed pretty vital. Mandy's 14.4 V Makita BHR162 was an obvious choice, and Ben had also offered the use of his Einhell BT-HD (handily the same voltage!), but what to do about batteries...

We were left with some obvious options:

Batteries:

- Proprietary

- Homemade Li-ion

- LiPo

Charging:

- Zabljak (at a campsite with power)

- Solar

- Generator

Our main requirements were a solution that primarily made drilling bolt placements feasible as the norm, without excessive battery conserving required. It seemed stupid to take a drill and not be able to use it as much as we'd like. The secondary requirements were that it was as lightweight as was sensibly feasible, reliable, and quite significantly that we were able to take it on a plane.

In terms of charging, solar power had got a lot more capable than it was a few years back, but still had its limitations. For contingency we could always have Zabljak as a backup charging option, but some sort of intermediate battery would be vital so we could charge drills batteries on cloudy days/overnight. To cope with the fluctuating solar output, the two obvious options were SLA batteries or LiFePO4. Obviously SLA have provided a nice cheap option, but coming in at 4 kg, plus the weight of the solar panels, the charge controller + chargers, it was vetoed based on the fact that for only a few kilos more we could probably take out the generator which wouldn't need a sunny day. It's also worth mentioning that we wouldn't have been able to fly with SLAs... Unfortunately Tesla and co seemed to be pricing LiFePO4 batteries out of our range, which was a shame given their capabilities. That would obviously be in addition to the not-insignificant cost of solar panels, and the fact that they'd almost certainly be redundant after a couple of years, so solar was off.

The generator was vetoed base on weight alone. At 9 kg it's pretty light for a generator. But at 9 kg + chargers + petrol, it was unlikely to charge its own weight in batteries.

That left us with charging either proprietary batteries or some other batteries in Zabljak. A few people tend to do a shopping run every 3-4 days, so whatever option we chose had to provide enough juice for 1 or 2 drills for that length of time, without being prohibitively heavy for the carry up with food.

Poprietary 14.4 V 3.0Ah Li-ion batteries for the Makita have enough juice for about thirteen 8 mm x 75 mm throughbolts, and weigh 500 g. To buy new they cost in the region of £80 (no way!) or for an ebay gamble, they're £20+ (really 3 Ah?!). Ben had made some external Li-ion 18650 packs for his Einhell with good results, getting 16 holes from a 7.8 Ah pack. We could obviously do the same for either/both drills, but flying with Li-ion batteries isn't that easy: they have to be in hand luggage and aren't allowed to be (visibly ;-) ) modified. We could have taken a gamble on putting them in the hold, but if the gamble didn't pay off it would have been a pain to say the least...but my soldering skills certainly weren't up to making a pack from scratch that looked "unmodified".

So what else? LiPo batteries were something I'd been pondering for a while, but I was a bit put off by speculative scare stories. They're used widely in remote control vehicles because of their high energy density, but they're known to be fairly catastrophic when things go wrong...

I was pretty surprised to see at their nominal voltage and capacity, they actually have a lower energy density than Li-ion, but this is mainly due to discharge rates; if they both discharge at the same rate then LiPo wins hands down. Having used LiPos for filming lights in Mexico, I had a couple of 5 Ah ones that handily were 14.8 V (Turnigy 5000mAh 4S1P 14.8v 20C hardcase). Time for some tests.

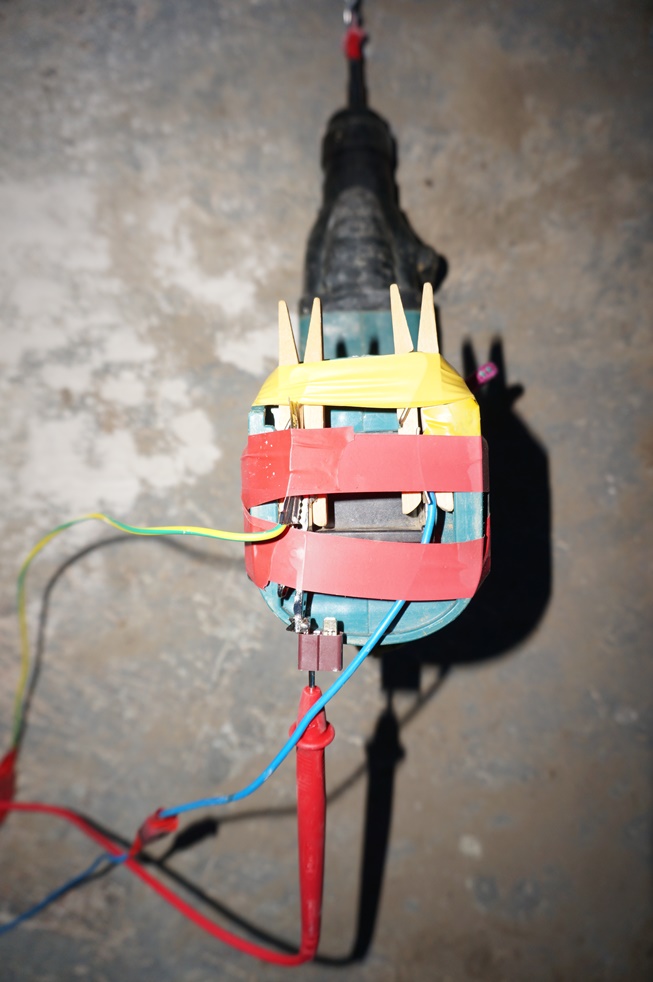

We were bit worried about frying the drill, because LiPos manage such high draws due to their minimal internal resistance (these were rated to 100 A continuous discharge!) so we started with the proprietary batteries to see what sort of volages/currents to expect. This required a pretty professional set-up.

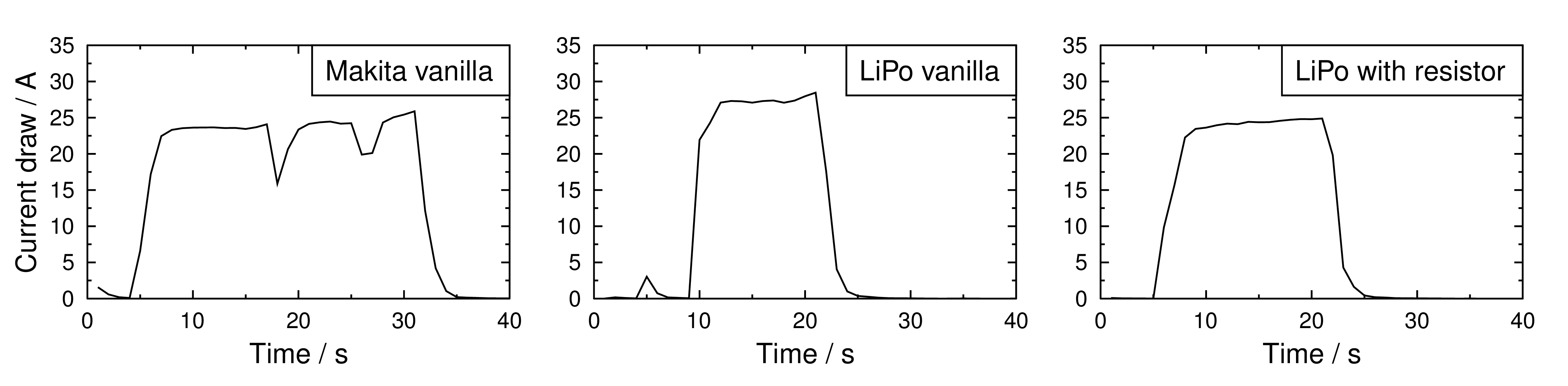

It was clear that the Li-ion voltages sagged pretty significantly under load (16.1 V resting & 12.6 V drilling) and that with no load on the drill we pulled 10 A, and whilst drilling we needed a steady 23 A or so. Wow.

We tentatively hooked up the LiPo and were pretty staggered by the difference it made to the feel of the drill given the nominal voltages and basic chemistries of the batteries were essentially the same. It was drilling holes at a pretty incredible rate, and the multimeter made it pretty clear why. The current through the drill was 27 A, and the battery voltage was up at 13.8 V even under full load. With a fair amount of waiting around to make sure we didn't risk overheating the drill, we found we could get 30 (!) holes from the battery which weighed roughly the same as the proprietary one which could drill 13... Certainly promising. but it was all very well with it all hooked up to a multimeter not drilling anything critical, but we were putting the best part of 30 % extra power through the drill, which hardly counted as a long term solution.

After messing around with inductors hoping to avoid some current spikes that turned out to be an artefact of the multimeter, we tried sticking a 50 mOhm resistor in the circuit to calm things down a little. Much as it grated to dissipate precious battery power through a resistor, it was clear from the massive gains from the LiPos that we could afford a bit of a loss. Time for another pro set-up.

Pleasingly, this calmed things down quite a lot, to the degree that we we're only putting about 10 % extra power through the drill compared to the proprietary batteries which, given the likely duty cycle of the drill on expo, seemed OK.

Since we got 30 holes from a battery connected directly, and we lost a steady 30 W through the resistor, we expected to get ~26 out of the new set-up. Not bad given it still weighed no more than a standard Makita battery :-)

Safety was obviously pretty critical for LiPos, and is mainly relevant if either the individual 3.7 V cells aren't balanced when they're charged, or the battery is over-discharged. The former was pretty easily overcome with any sensible charger, but the latter was potentially harder to deal with. Thankfully when the battery was connected directly (ie worst case) the drill stopped drilling at a safe voltage: at the end of the last bolt it was 9 V under load, but it recovered to 12.8 V (3.2 V per cell) after a little rest. No need to protect them :-)

For when we were out there, we bodged connectors to the drills using old Makita batteries and stuck the resistors in them. We then had batteries safely ensconced in tupperware boxes with long cables so they could stay in a tackle sack in use. If the worst case did happen and we did have a "vent with flame" situation, we'd hopefully lose nothing more than a tackle sack and some sphincteral tension.

This was the theory. We were quite tentative to start with, but it worked a treat, despite less than ideal conditions. The temperature was pretty hot outside, which will have resulted in maximum self-discharge, but in use the temperature underground was between 0 and 1 degree, maximising internal resistance. We also encountered an enormous amount of mud down one of the caves which meant that everything, battery connectors included, were totally covered in mud. Despite these conditions we found we were comfortably getting >20 throughbolt holes out of each battery, and we had no issues with battery safety whatsoever. The tupperware boxes did crack, but after wrapping them in rollmat and gaffer tape we had no more problems. Peli cases would obviously make more robust (but more expensive) containers. On a subsequent expedition to China we were placing 10 mm spit-style studs with the same set-up, and although we never actually completely discharged one, an extrapolation looked like we could get the best part of 40(!) bolts out of a battery.